Putting It All Together

Overview

This document provides a comprehensive overview of the key components that comprise the manufacturing workflow system. Understanding how these elements work together is essential for effective production management and scheduling.

Core System Components

Departments

Departments are logical groupings of workstations within your manufacturing organization. They serve as organizational units that help categorize and structure your workstations for better management and analysis. Currently, departments are used exclusively for reporting purposes, allowing you to group related workstations together and generate reports based on departmental organization.

Workstations

Workstations are the designated locations within your laboratory where similar work activities and production steps are performed. Each workstation represents a physical or logical area where specific types of production work occurs. Workstations have several key characteristics:

- Sequence Number: Determines the order in which workstations are scheduled within your production workflow

- Parallel Processing: Workstations with the same sequence number will be scheduled in parallel, allowing for simultaneous processing

- Next Workstations Configuration: Specifies which workstations the work will proceed to after the current workstation work is completed

- Work Assignment Types: Four distinct models for task distribution (Automatic, Manual Push, Manual Pull, and Custom)

- Location Tracking: Automatically updates case locations as work progresses through the facility

Production Template Steps

Production template steps are individual manufacturing steps that you track throughout your production process. These steps represent the granular tasks required to complete manufacturing operations. Each step has important attributes:

- Sequence Number: Defines the order of execution within a specific workstation

- Duration and Estimated Days: Time allocations for planning and scheduling

- Workstation Assignment: Links each step to the appropriate workstation location

- Outsourcing Capability: Some steps can be designated as outsourceable when needed

Production Templates

Production templates are groups of production template steps that define the complete manufacturing workflow for specific products. These templates serve as blueprints that standardize the production process, ensuring consistency and efficiency across your manufacturing operations.

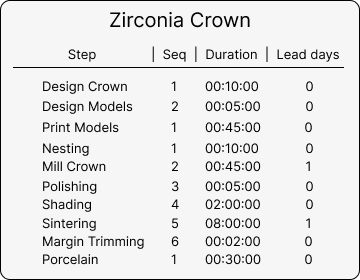

This example shows a production template for manufacturing a Zirconia Crown, displaying the sequential steps and their organization within the template structure. Each step is assigned to appropriate workstations with specific time allocations and sequence ordering.

Templates provide several benefits:

- Standardization: Ensures consistent manufacturing processes across all cases

- Automation: Automatically generates detailed production schedules when products are added to cases

- Quality Control: Maintains consistent workflow standards for each product type

- Resource Management: Optimizes workstation utilization and technician assignments

User Capacity and Scheduling

Users (technicians) within Pilot have specific characteristics that directly impact production scheduling and capacity planning:

- Work Shifts: Defined time periods when technicians are available to perform work

- Capacity Multiplier: A numerical factor that determines how many steps a technician can complete within their shift period

- Workstation Assignments: Each technician is assigned to specific workstations where they can perform work

Pilot uses these user characteristics in combination with workstation assignment types to automatically distribute work and optimize resource utilization.

Production Schedule Generation

When a product is added to a case, Pilot performs automated production schedule generation based on the integrated components described above:

- Template Selection: Pilot retrieves all production steps from the product's default production template

- Workstation Routing: Steps are routed through workstations based on sequence numbers and next workstation configurations

- Resource Allocation: Technicians are assigned to steps based on their workstation assignments, availability, and capacity multipliers

- Timeline Calculation: Completion dates are calculated using step durations, estimated days, and technician capacity

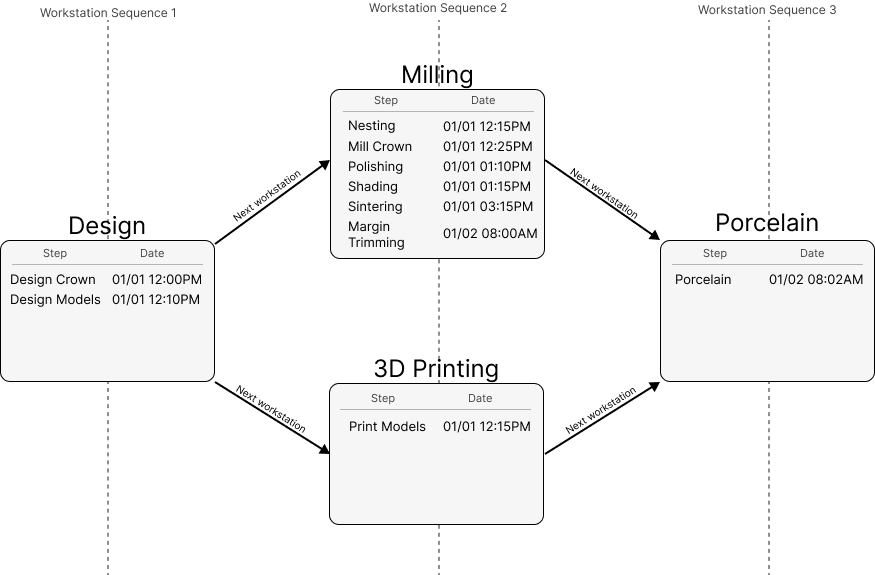

This sample production schedule demonstrates how Pilot combines template steps, workstation sequencing, and technician assignments to create a comprehensive timeline for case completion. The schedule shows step names, assigned workstations, scheduled dates, and technician assignments in an organized, trackable format.

System Integration Benefits

The integration of these components creates a powerful manufacturing management system that provides:

- Automated Workflow Management: Cases automatically flow through your facility following predefined routes with minimal manual intervention.

- Resource Optimization: Technician assignments and workload distribution are optimized based on capacity, availability, and workstation configurations.

- Real-time Tracking: Cases and their current locations are tracked automatically as work progresses through different workstations.

- Scalable Structure: The modular design allows for easy expansion and modification of production workflows as business needs evolve.

- Consistent Quality: Standardized templates ensure that every product follows the same proven manufacturing process.

- Flexible Assignment Models: Multiple work assignment types accommodate different management styles and operational requirements.

Best Practices for Implementation

To maximize the effectiveness of your manufacturing system:

- Design templates that accurately reflect your actual manufacturing processes

- Configure workstation sequences that match your physical facility layout and workflow requirements

- Set realistic capacity multipliers based on actual technician performance data

- Regularly review and update step durations based on completion time analysis

- Establish clear routing rules for complex workflows with multiple possible paths

- Train technicians on the appropriate work assignment model for their workstations

- Use departmental organization to facilitate meaningful performance reporting and analysis